A laminar flow hood, also known as a clean bench, is a piece of laboratory equipment designed to provide a sterile work environment for various applications, such as cell culture, sample preparation, and other processes that require aseptic conditions. It achieves this by maintaining a constant flow of highly filtered air over the work surface, preventing contamination from the surrounding environment.

What is a laminar flow hood?

Laminar flow hood is enclosed workbench, designed to provide an aseptic work environment to meet varying research and clinical requirements. The filtered airflow protects the sample from airborne contamination and produces the cleanest, most germ-free laboratory environment possible.

They are used in a variety of industries, including:

- Pharmaceuticals: To manufacture sterile drugs and other medical products.

- Biotechnology: To culture cells and microorganisms for research and development.

- Food and beverage: To produce sterile food and beverages.

- Electronics: To assemble and test electronic components.

- Cosmetics: To manufacture sterile cosmetics.

How does a laminar flow hood work?

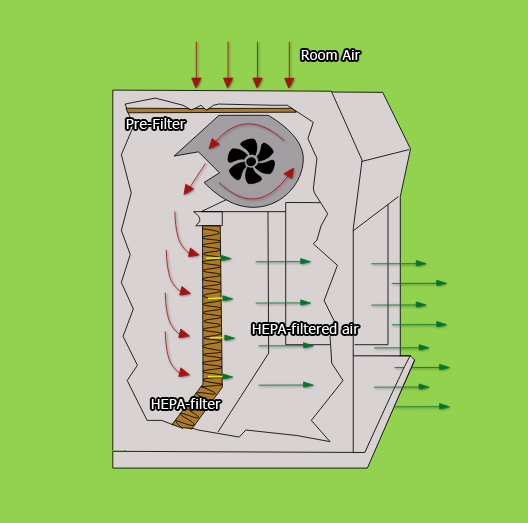

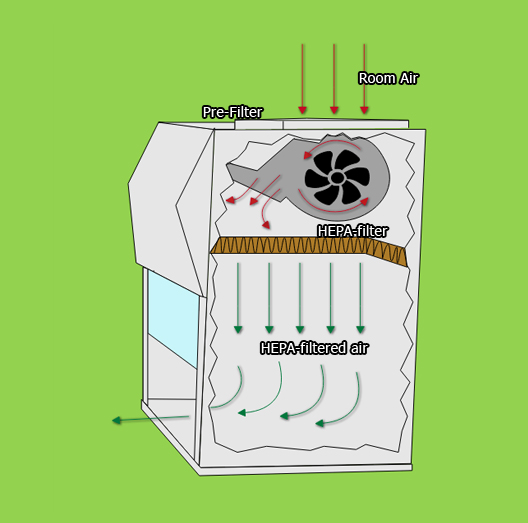

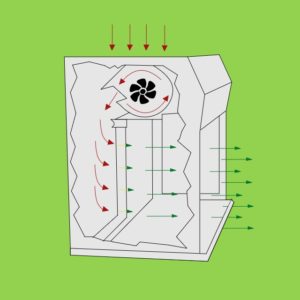

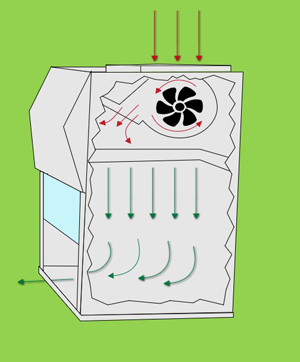

**1. ** Airflow Direction: Laminar flow hoods can have vertical or horizontal airflow. In a vertical hood, air moves from the top of the hood to the work surface and then out through a HEPA (High-Efficiency Particulate Air) filter at the bottom. In a horizontal hood, air moves from the back of the hood to the front, creating a curtain of clean air across the work surface.

**2. ** HEPA Filters: The heart of a laminar flow hood is the HEPA filter. HEPA filters are highly efficient at trapping particles, including bacteria, viruses, and other contaminants. The filter removes airborne particles larger than a certain size (usually 0.3 micrometers) with a high-efficiency rate, typically 99.97%. As the surrounding air is drawn into the hood, it passes through the HEPA filter, removing contaminants and providing a continuous clean air supply.

**3. ** Constant Airflow: The laminar flow hood maintains a continuous, unidirectional airflow. This means that air moves steadily over the work surface in one direction, carrying away any contaminants that might be present. This constant flow of clean air creates a sterile environment for the work inside the hood.

**4. ** Sterile Workspace: The laminar flow of clean air creates a workspace where researchers can perform tasks without the worry of contamination from the environment. This is crucial in applications like microbiology, cell culture, and electronics assembly, where even a small particle or microorganism can ruin experiments or processes.

It’s important to note that while laminar flow hoods are excellent for protecting the work inside from contamination, they do not protect the user. Proper aseptic techniques, personal protective equipment, and other safety measures are still necessary when working with hazardous materials or organisms.

The benefits of using a laminar clean bench:

- Product protection

- Create an ISO Class 5 working environment

- Space-saving tool

There are available two laminar flow types in horizontal or vertical airflow configurations. When to use horizontal or vertical laminar clean bench?

They both protect the products on the work surface against particles and particulates, but which one is best for your specific needs can come down to personal preferences.

How does a horizontal laminar flow cabinet work?

In Horizontal flow hoods, filtered air moves from the back; it passes through a HEPA filter and runs onto the work surface in a horizontal direction. This type of hood protects the substances from contamination, but there is a risk for the operator. Because of the horizontal airflow, there is a risk contaminates to blow into the operator’s face

The horizontal laminar clean bench might be best for you when:

- Your applications require minimal turbulence

- Using small equipment that will not cause airflow disturbance

In Vertical laminar flow cabinets, a HEPA filter is mounted above the work surface, delivering airflow in a downward motion. This way improves the effect of gravity and expels particles from the enclosure.

Copyright ©2020 Laboratory-Report.com. All Rights Reserved

The vertical laminar flow might be best for you when:

- Working with larger equipment as the workspace is taller more in-depth. Because of the filter position, it produces less turbulence with bigger

- Working with applications that produce vapors or fumes:

- When you need operator protection. It’s included sash protector.

- When you are using compounding sterile products

Choosing a vertical or horizontal laminar flow depends on the type of process location, operator safety, clearance requirements and work surface design.

Laminar Flow Hood Types – Clean Benches

What is the difference between a fume hood and laminar flow?

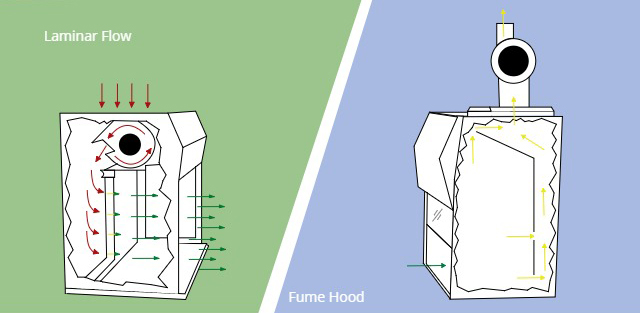

Laminar Flow and Laboratory Fume hoods are essential equipment in laboratories, designed to work on a similar principle. They both operate on a constant flow of air to prevent contamination, but knowing the difference is essential for keeping a safe environment for everyone in your laboratory.

Here are more specific differences between a fume hood and a laminar clean bench hood:

Airflow pattern

In fume hoods, room air enters through the sash into the work area.

The airflow pushes the toxic fumes, gases and vapors toward the exhaust area, where they are expelled from the lab through exhaust fume hoods. The toxic air is diluted before getting released outdoors.

In a laminar clean bench, pure air continually passes. As it passes through the HEPA filter, it becomes purified. Airborne particulates are removed by the filters s these can otherwise cause sample contamination.

In contrast, laminar flow hoods have two patterns of airflow: horizontal and vertical airflow.

HEPA filtered air in horizontal laminar flow hoods flows the air sideways within the cabinet. Usually, a horizontal clean bench is used for creating sterilized mediums, particularly in clinic laboratories. HEPA filtered-air in vertical flow hoods direct the flow of air downwards towards the workbench.

Protection

Laminar flow is used to protect the delicate substances from contamination but does not protect the user from chemically hazardous or infectious materials.

The hood is designed to protect users from chemical exposure only when utilized properly. A Fume hood only reduces the exposure of laboratory workers to potential hazards (flammable and toxic chemical agents). When it comes to the airflow of the hood, it is always better to avoid disrupting the flow of air. Avoid large containers that could obstruct the motion of the air. When toxic fumes and gases are used, it is not safe for lab users to put their heads inside the hood, for a reason.

Fume hoods only protect the lab worker from substances that could cause toxicity. The exhaust fume hood releases gases from the work station. Fume hoods don’t control the environment of the delicate materials as much as laminar clean bench hoods do.

Clean Air Workstations serve this purpose. It also shields the lab worker from substances that could be harmful and provides environmental protection in the process.

In general, fume hoods provide protects the laboratory workers, and laminar flow delivers sample protection.

Uses

When differentiating the fume hood from the laminar flow, keep in mind that both types are used for protecting delicate substances from getting contaminated.

This vertical flow is typically used for drug preparations in assembling industries. Fume hoods are used for chemical handling or toxic-fumes released by experimental reactions. For example, a fume hood helps control carcinogenic substances.

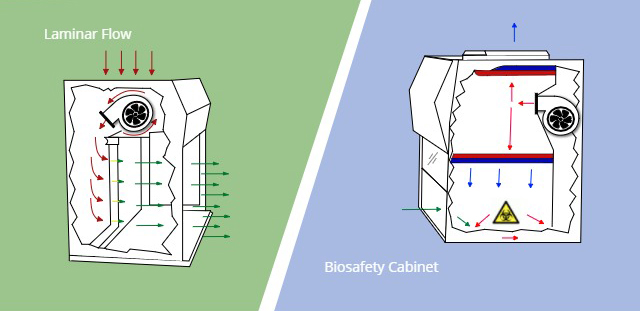

What is the difference between a bio-safety cabinet and laminar flow?

Laminar flow and bio-safety cabinets seem to do such similar activities that it can sometimes be hard to tell which is which. However, these two laboratory equipment types do very different things.

For one thing, bio-safety cabinets create a one-direction airlow across the surface of work according to a parallel pattern. However, laminar flow cabinets are not bio-safety cabinets.

Instead, laminar flow is designed to protect the work on the work surface. They do not protect the worker or the lab technician as the flow of air pushes particulates and aerosols from the work surface towards the worker.

When there is a requirement for biological safety, a class 2 type A2 NSF certificate for protecting the environment, personnel and work surface are recommended. This way, the worker and the lab get protected from biological and airborne particulates.

Negative pressure within the cabinet is maintained within the experiment or lab work so that no contaminant can escape the area enclosure. This set-up is ideal for various biological protocols, life science researchers and for preparing sterile products in multiple industries.

There are 3 types of bio-safety cabinets.

• Class 1- In this type, the flow of air goes from the lab into the chamber.

• Class 2- In this type, airflow from the lab into the chamber while at the same time flowing downwards towards the surface for work. The air exhaust is formed before passing through HEPA filters and then getting released to the environment. The air which is filtered can also be recirculated back within the chamber.

• Class 3- in this type of cabinet, the air that exits or enters the chamber first passes through HEPA filters.

How long should a laminar flow hood run before using?

As a general rule, laminar hoods should stay on all day. If, for some reason, they are off, turn it on for a minimum of 30 minutes and cleaned thoroughly before re-using. Remember, carelessness can reverse air current and cause contaminants to flow back into the working area.

Remember that air control in the environment is essential because the air in the room could be extremely contaminated. For example, sneezing produces air droplets of up to 200,000 that attach themselves to particles of dust.

These particles are contaminated and could remain in the air week after week. Remember what happens when you suddenly open the curtains on a clear day? Dust particles scatter everywhere. Properly used, your laminar flow hood cabinet’s HEPA filter should remove almost all bacteria from the air.